Bosch measuring technology

| Resolution of infrared sensor | 160 x 120 |

| Thermal sensitivity | < 50 mK |

| Measuring range | -10 °C … +400 °C |

- Tool

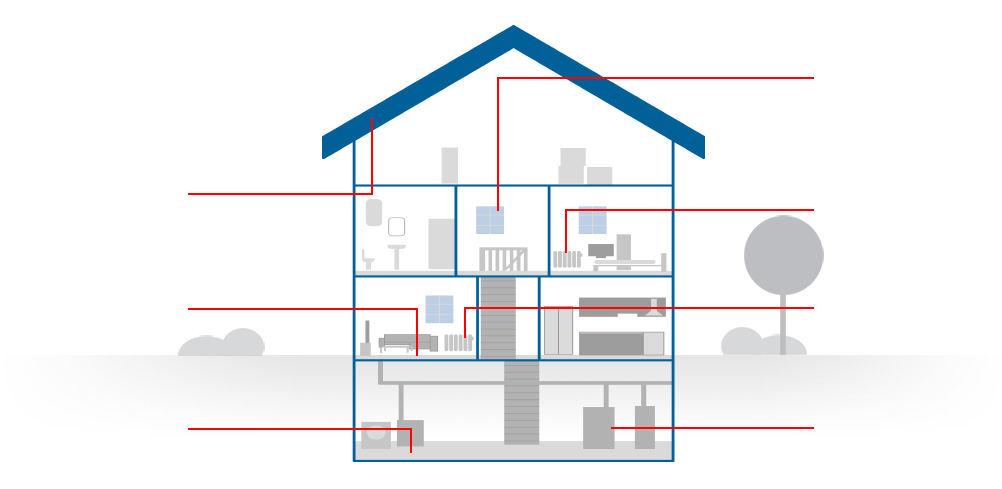

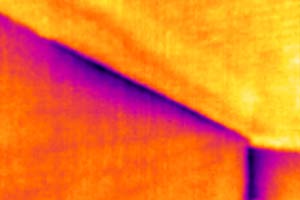

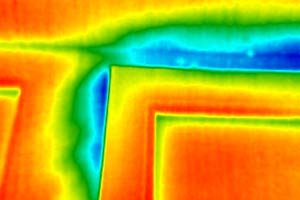

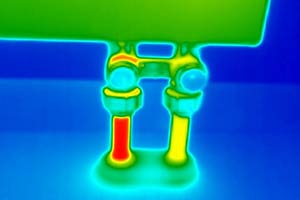

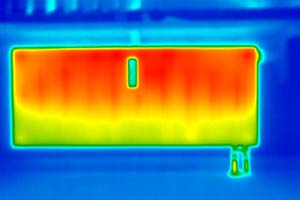

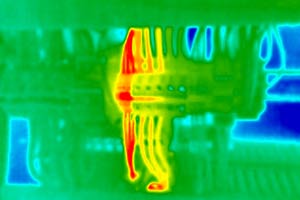

The tool measures the surface temperature of objects and displays it as a thermal image. This provides a clear and simple overview of heat distribution and differences in temperature.

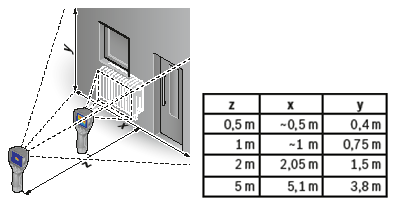

The figure below shows the camera's field of view, so that you can estimate the size of the measurement range (x and y) at a particular distance (z).

In principle, the thermal resolution works in the same way as a normal camera, i.e. we can measure 160 pixels horizontally and 120 pixels vertically. That is a total of 19200 measurement pixels, each of which contains a temperature value. These measurement pixels are put together to form a thermal image which is shown in the display.

As far as thermal sensitivity is concerned, smaller is better. This value specifies the differences in temperature that can be measured between pixels. < 50 mK means that temperature differences of < 0.05 °C can be measured using the GTC 400 C Professional. It therefore allows very subtle and slight deviations in temperature to be detected.

Measurement starts as soon as the tool has been switched on.

If you would like a still image, or want to freeze the image, simply press the trigger to view the image in peace. To continue measurement, press the trigger again.

If you would like to save the image on the tool, just press  the button. This is possible both during the measurement and also when viewing a still or frozen image.

the button. This is possible both during the measurement and also when viewing a still or frozen image.

The closer the tool is to the measurement object, the more precise the measurement. At relatively large distances, the measurement results can be more imprecise, as a result of high humidity, for example, which can influence the result.

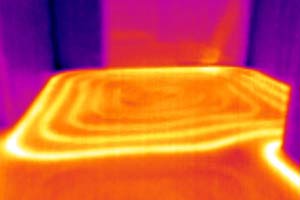

The thermal imaging camera shows you the temperature differences. The larger the deviation in temperatures, the more this is made apparent in your thermal image. If you would like to make the heating pipes in an underfloor heating system visible, for example, it is best to switch this system off, allow the floor to cool and then switch it back on at the highest setting. This will give you the best view of the heating pipes.

Thanks to the built-in real image camera, for every thermal image (…X.jpg) a real image (…Y.jpg) is also saved. This makes it easier for you to identify any objects which are unclear in the thermal image.

In addition, the raw data of the temperatures is also stored in the real image. Each pixel therefore has a temperature value stored in it and if you like, you can easily edit the real images (…Y.jpg) in our free GTC Transfer Software. You can also effortlessly create an evaluation or report. The software can be found here.

For optimum results, configure the tool by selecting the material you are measuring (emissivity). There is a selection list of the most common materials and their associated emissivity stored on the GTC 400 C. However, it is possible to enter user-defined values. A range of common materials is also provided in the user manual

A thermal image camera like the GTC 400 C can be used to measure the temperature distribution of a relatively large area. Thousands of measurement points are compiled in an image and provide a rapid overview of critical areas. For example, it helps to rapidly identify problems in areas where temperature differences have to be located.

Point measurement using the GIS 1000 C Professional accurately measures the surface temperature of a small area. If necessary, the relative humidity and ambient temperature can also be measured (depending on the application). The GIS 1000 C Professional is therefore suitable for precise point measurements. It aids detailed analysis of small areas and localised measurements.

Yes, every version contains such a certificate in the user manual, which confirms that the tool functions within the specifications of the user manual.

I don't think my tool is working properly. Can it be recalibrated? Bosch Service Centre.

Yes, you can contact your service centre to request a calibration and will receive a calibration certificate as proof. To find out whether this service is available in your area, please contact your nearest Bosch Service Centre.

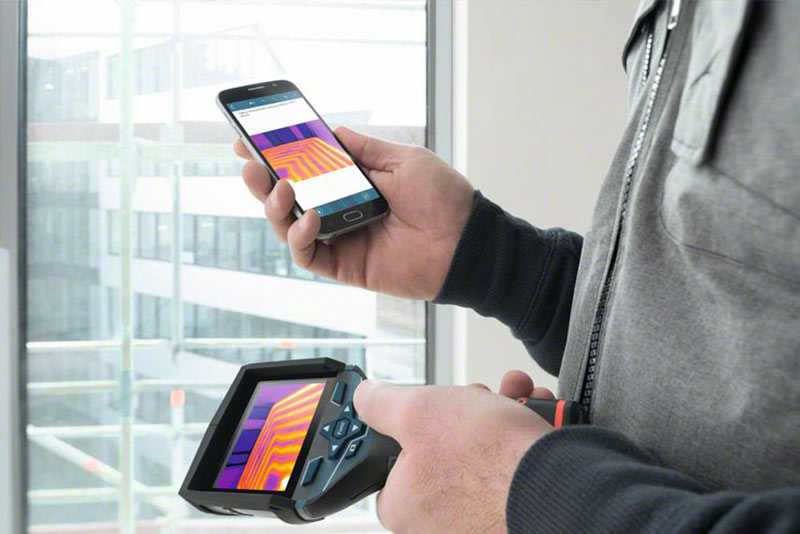

The Measuring Master app can be downloaded in the Apple App Store and in the Google Play Store.

The app is only available for Android and iOS tablets and smartphones. Other operating systems are not supported. Supported Android devices: Bluetooth®-enabled smartphones and tablets from Android 4.3. Supported iOS devices: iPhone (4S or higher), iPad (3rd Gen. or higher), iPad Air (1st Gen. or higher), iPad mini (1st Gen. or higher).

The projects are stored on the smartphone/tablet they were created on and cannot be transferred to other devices.

Yes, your data will be retained when a software update is performed.

Saved content is always retained. To be safe, before you perform an update, you should save the projects on your laptop/PC by “sharing” them and forwarding them as a PDF or Excel file to your e-mail address.

Go to “Settings” → “Language” to see which languages the app is available in.

Export

Export

Settings

Settings

Establish Bluetooth® connection

Establish Bluetooth® connection

To establish a connection between your thermal imaging camera and your smartphone/tablet, please activate the WLAN connection on both devices. The WLAN function on the GTC 400 C Professional can be activated via the camera's tool settings. Once WLAN is activated on your thermal imaging camera, the connection key is shown at the bottom of the tool display. Make sure that WLAN is activated on your smartphone/tablet. Then open the thermal imaging function in Measuring Master and tap on the WLAN symbol in the app to establish a connection between the two devices. Now follow the instructions in the app.

The images can be transferred to a PC via the GTC 400 C Professional's micro-USB port and viewed on the PC. For Windows operating systems (Windows 7, Windows 8, Windows 10), we also provide the free GTC Transfer Software, with which you can edit and document your saved thermal images. The software can be downloaded here

No, you can only use one thermal imaging camera with the app at any time.

Depending on on-site conditions (obstacles, humidity, radio interference, etc.), it is possible to maintain a connection between your smartphone/tablet and the thermal imaging camera over a range of up to 50 m.

If the tool has been connected to the smartphone/tablet before, the two devices will connect automatically as long as WLAN is activated on both devices, the devices are within range and the smartphone/tablet is not connected to any other WLAN network.

First establish a WLAN connection between Measuring Master and your GTC 400 C Professional (see “How do I establish a connection between the GTC 400 C Professional and my smartphone/tablet?”). Then, in the “Thermal image” function, tap on the “+” to import a thermal image from the GTC 400 C Professional.

With  you can select objects in the thermal image (e.g. notes, markings) in order to edit or delete them.

you can select objects in the thermal image (e.g. notes, markings) in order to edit or delete them.

With  you can select objects in the thermal image (e.g. notes, markings) in order to edit or delete them.

you can select objects in the thermal image (e.g. notes, markings) in order to edit or delete them.

Under  you can add notes and tasks to your thermal image and add text labels directly in the image.

you can add notes and tasks to your thermal image and add text labels directly in the image.

Under  you can undo actions.

you can undo actions.

Under  you can redo undone actions.

you can redo undone actions.

Under  you can delete selected objects.

you can delete selected objects.

If the following functions have been activated for image capture on the GTC 400 C Professional, these will also be displayed in the app.

Hotspot: The hottest point in the thermal image is automatically marked by red crosshairs.

Hotspot: The hottest point in the thermal image is automatically marked by red crosshairs.

Cold spot: The coldest point in the thermal image is automatically marked by blue crosshairs.

Cold spot: The coldest point in the thermal image is automatically marked by blue crosshairs.

Crosshairs with temperature display: The crosshairs are displayed in the centre of the thermal image and show you the measured temperature value at this point.

Crosshairs with temperature display: The crosshairs are displayed in the centre of the thermal image and show you the measured temperature value at this point.

Emissivity: This specifies how much infrared thermal radiation is emitted by the object compared to an ideal thermal emitter (black body, emissivity degree = 1).

Emissivity: This specifies how much infrared thermal radiation is emitted by the object compared to an ideal thermal emitter (black body, emissivity degree = 1).

Reflected temperature: The reflected temperature is the thermal radiation that is not emitted by the object itself. This generally corresponds to the ambient temperature.

Reflected temperature: The reflected temperature is the thermal radiation that is not emitted by the object itself. This generally corresponds to the ambient temperature.