Changing the tool

- Wear protective gloves when changing accessories. There is a risk of injury when touching the accessories.

Please observe the accessories intended for your power tool.

Accessory | GOP 185‑LI |

|---|---|

|

|

|

|

|

|

The following table shows examples of accessories. You can find additional accessories in Bosch’s extensive range of accessories.

Accessory | Material | Application | |

|---|---|---|---|

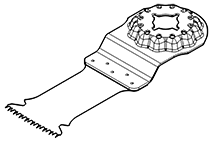

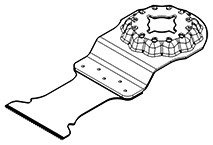

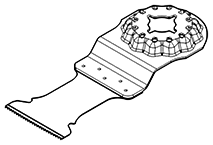

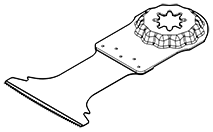

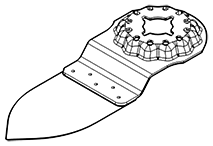

| AIZ 10 AB | Softwood, soft plastics, gypsum, thin-walled aluminium and non-ferrous metal profiles, thin metal sheets, non-hardened nails and bolts | Smaller separation and plunge cuts; delicate adjustment work in wood; |

| AIZ 32 EPC | Softwood | Splinter-free separation and plunge saw cuts thanks to round sawing edge (Curved-Tec); also for sawing close to the edge, in corners and difficult-to-access areas; |

| AIZ 32 APB/ | Composite materials made from wood and soft non-ferrous metals, unhardened nails and screws, pipes made from non-ferrous metal and profiles with small dimensions | Tear-free flush cuts and plunge cuts in wood, soft non-ferrous metals and plastic thanks to round sawing edge (Curved-Tec); |

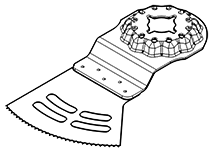

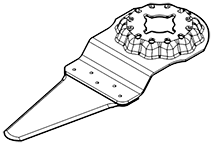

| PAIZ 32 APB | Composite materials made from wood and soft, non-ferrous metals, unhardened nails and bolts, pipes made from non-ferrous metal and profiles of smaller dimensions | Quick and deep plunge cuts in wood, abrasive wooden materials and plastics, splinter-free work thanks to round cutting edge (Curved-Tec); |

| AIZ 32 BSPB/ | Hardwood, laminated boards | Splinter-free separation and plunge cuts in coated boards or hardwood thanks to round sawing edge (Curved-Tec), Japan toothing specially suited for hardwood; |

| AIZ 32 AT/AIZ 32 AIT | Hard ferrous metals, extremely abrasive materials, fibreglass, plasterboard, cement-bonded fibreboards, hardened nails and screws | Sawing extremely abrasive materials or hard ferrous metals; long service life thanks to BOSCH carbide technology; |

| AIZ 32 APT/AIZ 32 APIT | Hard ferrous sheet metal, epoxy, plasterboard, GFRP, CFRP, cement fibreboard | Splinter-free separating cuts and plunge cuts in sheet metal thanks to round sawing edge (Curved-Tec); long service life thanks to BOSCH carbide technology; |

| PAIZ 45 AT/PAIZ 45 AIT | Hard ferrous metals, extremely abrasive materials, fibreglass, plasterboard, cement-bonded fibreboards, hardened nails and screws | Wide saw blade for sawing highly abrasive materials or hard ferrous metals; long service life thanks to BOSCH carbide technology; |

| PAII 52 APT/PAII 52 APIT | Hard ferrous sheet metal, epoxy, plasterboard, GFRP, CFRP, cement fibreboard | Long saw blade for splinter-free separation and plunge cuts in sheet metal thanks to round sawing edge (Curved-Tec); long service life thanks to BOSCH carbide technology; |

| AYZ 53 BPB | Gypsum boards, chipboards, sandwich material, wood | Optimised for plunge saw cuts with a subsequent longer separation cut; the Dual-Tec shape ensures a clean and complete cut both in the corners and during a longer separation cut; |

| AII 65 APB/ | Softwood, hardwood, veneered boards, plastic-coated boards, non-hardened nails and bolts | Splinter-free separation and plunge cuts thanks to round sawing edge (Curved-Tec) in coated boards or hardwood; |

| ACZ 85 EB/ | Wooden materials, plastic, soft and non-ferrous metals | Separation and plunge saw cuts; |

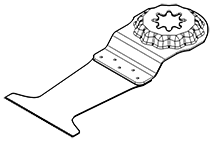

| ACZ 100 SWB | Insulation material, insulation boards, floor panels, impact sound insulation boards, cardboard, carpets, rubber, leather | Precise cutting of soft materials; |

| ACZ 105 ET | Fibre cement boards, tile joints, brick, fibreglass-reinforced plastics, laminate | Separation and plunge saw cuts; also for sawing close to the edge in difficult-to-access areas; long service life thanks to BOSCH Carbide Technology; |

| ACZ 70 RT5 | Thin tile joints, porous concrete, soft brick, cement fibreboards, fibreglass-reinforced plastics, epoxy | Cutting and separating with a particularly thin blade (1.6 mm) in areas and corners that are close to the edge or difficult to access, long service life thanks to Carbide-RIFF; |

| ACZ 85 RD4 | Cement joints, soft wall tiles, fibreglass-reinforced plastics, epoxy, GKF | Cutting and separating in areas and corners that are close to the edge or difficult to access, extra long service life thanks to Diamond-RIFF; |

| AVZ 70 RT4 | Mortar, joints, epoxy resin, fibreglass-reinforced plastics, abrasive materials | Reaming and separating joint and tile material, as well as rasping and sanding on a hard substrate; long service life thanks to BOSCH carbide technology; |

| AVZ 90 RT2 | Mortar, concrete residue, wood, abrasive materials, paint | Rasping and sanding on a hard substrate; |

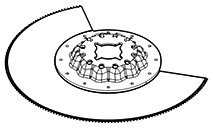

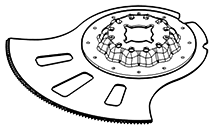

| AVZ 93 G | Depends on the sanding sheet | Sanding on edges, in corners or in difficult-to-access areas; Orbital stroke rate level "4" is the maximum level that should be used when sanding. If the orbital stroke rate is too high, this will considerably increase the wear of the accessory and can also lead to premature breakdown. |

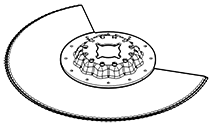

| AUZ 70 G | Wood, pipes/profiles, paint, varnish, filler, metal | Convenient and efficient sanding of profiles and curved, uneven material surfaces up to a diameter of 55 mm; |

| AVZ 32 RT4 | Wood, paint | Sanding wood or paint in difficult-to-access places without sanding paper; long service life thanks to BOSCH carbide technology; |

| AIZ 28 SC | Expansion joints, window putty, insulation materials (rock wool) | Cutting soft materials; |

| ASZ 32 SC | Roofing felt, carpets, artificial turf, cardboard, PVC flooring | Quick and precise cutting of soft material and flexible, abrasive materials; |

| ATZ 52 SC | Carpets, mortar, concrete, tile adhesive | Scraping on a hard substrate; |

Remove the accessory if one has already been fitted.

To do so, open the Starlock lever (7) all the way. The accessory will be ejected.

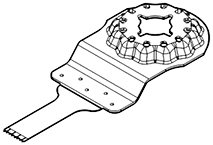

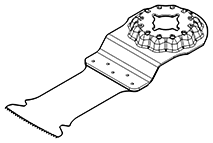

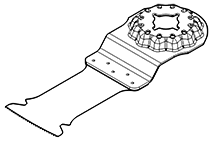

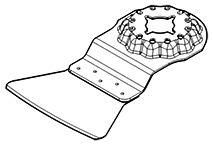

Position the required accessory (e.g. plunge cut saw blade (12)) on the tool holder (8) so that the depressed centre is facing downwards (see figure on the graphics page, text on the accessory should be legible from above).

When doing so, place the accessory in a position which is convenient for the job at hand. Twelve positions offset by 30° are possible for this.

Press the accessory in the required position firmly onto the clamping jaws of the tool holder until it locks automatically.

- Check that the accessory is seated securely. Accessories that are attached incorrectly or are not securely fixed in place may come loose during operation, thereby putting you at risk.

The depth stop (11) can be used when working with segment and plunge cut saw blades.

Remove the accessory if one has already been fitted.

Slide the depth stop (11) into the required working position over the tool holder (8) and onto the collar of the power tool as far as it will go. Allow the depth stop to engage. Twelve positions offset by 30° are possible for this.

Set the depth you wish to work at. Push the clamping lever (10) of the depth stop shut to fix the depth stop in position.

Different sanding sheets are available, depending on the material you are working with and the required surface removal rate:

Sanding sheet | Material | Application | Grit | |

|---|---|---|---|---|

|

| For pre-sanding, e.g. of rough and uneven beams and boards | Coarse | 40 |

For surface sanding and levelling of slight irregularities | Medium | 80 | ||

For finish-sanding and fine sanding of wood | Fine | 180 | ||

|

| For sanding down paint | Coarse | 40 |

For sanding undercoats (e.g. removing brushstrokes, paint drips and paint runs) | Medium | 80 | ||

For final sanding of primers prior to painting | Fine | 180 | ||

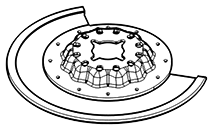

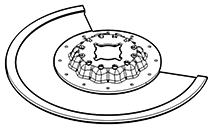

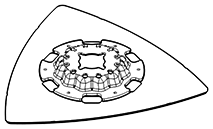

The sanding plate (14) is fitted with a hook-and-loop fastening, allowing sanding sheets with a hook-and-loop backing to be secured quickly and easily.

Tap the hook-and-loop fastening of the sanding plate (14) before fitting the sanding sheet (15) to facilitate maximum adhesion.

Position the sanding sheet (15) so that it is flush with one side of the sanding plate (14), then place the sanding sheet on the sanding plate and press it on firmly.

To ensure optimum dust extraction, make sure that the punched holes in the sanding sheet are aligned with the drilled holes in the sanding plate.

To remove the sanding sheet (15), take hold of it by a corner and pull it away from the sanding plate (14).

You can use all sanding sheets, polishing and cleaning fleeces from the Delta 93 mm series in the Bosch range of accessories.

Sanding accessories such as fleece/polishing felt are attached to the sanding plate in the same way.

Orbital stroke rate level "4" is the maximum level that should be used when working with sanding accessories such as sanding sheets and sanding plates. If the orbital stroke rate is too high, this will considerably increase the wear of the accessory and can also lead to premature breakdown. Please take note of the information on the accessory or on the packaging of the accessory.

Accessory | Material | Application | |

|---|---|---|---|

| AIZ 10 AB | Softwood, soft plastics, gypsum, thin-walled aluminium and non-ferrous metal profiles, thin metal sheets, non-hardened nails and bolts | Smaller separation and plunge cuts; delicate adjustment work in wood; |

| AIZ 32 EPC | Softwood | Splinter-free separation and plunge saw cuts thanks to round sawing edge (Curved-Tec); also for sawing close to the edge, in corners and difficult-to-access areas; |

| AIZ 32 APB/ | Composite materials made from wood and soft non-ferrous metals, unhardened nails and screws, pipes made from non-ferrous metal and profiles with small dimensions | Tear-free flush cuts and plunge cuts in wood, soft non-ferrous metals and plastic thanks to round sawing edge (Curved-Tec); |

| PAIZ 32 APB | Composite materials made from wood and soft, non-ferrous metals, unhardened nails and bolts, pipes made from non-ferrous metal and profiles of smaller dimensions | Quick and deep plunge cuts in wood, abrasive wooden materials and plastics, splinter-free work thanks to round cutting edge (Curved-Tec); |

| AIZ 32 BSPB/ | Hardwood, laminated boards | Splinter-free separation and plunge cuts in coated boards or hardwood thanks to round sawing edge (Curved-Tec), Japan toothing specially suited for hardwood; |

| AIZ 32 AT/AIZ 32 AIT | Hard ferrous metals, extremely abrasive materials, fibreglass, plasterboard, cement-bonded fibreboards, hardened nails and screws | Sawing extremely abrasive materials or hard ferrous metals; long service life thanks to BOSCH carbide technology; |

| AIZ 32 APT/AIZ 32 APIT | Hard ferrous sheet metal, epoxy, plasterboard, GFRP, CFRP, cement fibreboard | Splinter-free separating cuts and plunge cuts in sheet metal thanks to round sawing edge (Curved-Tec); long service life thanks to BOSCH carbide technology; |

| PAIZ 45 AT/PAIZ 45 AIT | Hard ferrous metals, extremely abrasive materials, fibreglass, plasterboard, cement-bonded fibreboards, hardened nails and screws | Wide saw blade for sawing highly abrasive materials or hard ferrous metals; long service life thanks to BOSCH carbide technology; |

| PAII 52 APT/PAII 52 APIT | Hard ferrous sheet metal, epoxy, plasterboard, GFRP, CFRP, cement fibreboard | Long saw blade for splinter-free separation and plunge cuts in sheet metal thanks to round sawing edge (Curved-Tec); long service life thanks to BOSCH carbide technology; |

| AYZ 53 BPB | Gypsum boards, chipboards, sandwich material, wood | Optimised for plunge saw cuts with a subsequent longer separation cut; the Dual-Tec shape ensures a clean and complete cut both in the corners and during a longer separation cut; |

| AII 65 APB/ | Softwood, hardwood, veneered boards, plastic-coated boards, non-hardened nails and bolts | Splinter-free separation and plunge cuts thanks to round sawing edge (Curved-Tec) in coated boards or hardwood; |

| ACZ 85 EB/ | Wooden materials, plastic, soft and non-ferrous metals | Separation and plunge saw cuts; |

| ACZ 100 SWB | Insulation material, insulation boards, floor panels, impact sound insulation boards, cardboard, carpets, rubber, leather | Precise cutting of soft materials; |

| ACZ 105 ET | Fibre cement boards, tile joints, brick, fibreglass-reinforced plastics, laminate | Separation and plunge saw cuts; also for sawing close to the edge in difficult-to-access areas; long service life thanks to BOSCH Carbide Technology; |

| ACZ 70 RT5 | Thin tile joints, porous concrete, soft brick, cement fibreboards, fibreglass-reinforced plastics, epoxy | Cutting and separating with a particularly thin blade (1.6 mm) in areas and corners that are close to the edge or difficult to access, long service life thanks to Carbide-RIFF; |

| ACZ 85 RD4 | Cement joints, soft wall tiles, fibreglass-reinforced plastics, epoxy, GKF | Cutting and separating in areas and corners that are close to the edge or difficult to access, extra long service life thanks to Diamond-RIFF; |

| AVZ 70 RT4 | Mortar, joints, epoxy resin, fibreglass-reinforced plastics, abrasive materials | Reaming and separating joint and tile material, as well as rasping and sanding on a hard substrate; long service life thanks to BOSCH carbide technology; |

| AVZ 90 RT2 | Mortar, concrete residue, wood, abrasive materials, paint | Rasping and sanding on a hard substrate; |

| AVZ 93 G | Depends on the sanding sheet | Sanding on edges, in corners or in difficult-to-access areas; Orbital stroke rate level "4" is the maximum level that should be used when sanding. If the orbital stroke rate is too high, this will considerably increase the wear of the accessory and can also lead to premature breakdown. |

| AUZ 70 G | Wood, pipes/profiles, paint, varnish, filler, metal | Convenient and efficient sanding of profiles and curved, uneven material surfaces up to a diameter of 55 mm; |

| AVZ 32 RT4 | Wood, paint | Sanding wood or paint in difficult-to-access places without sanding paper; long service life thanks to BOSCH carbide technology; |

| AIZ 28 SC | Expansion joints, window putty, insulation materials (rock wool) | Cutting soft materials; |

| ASZ 32 SC | Roofing felt, carpets, artificial turf, cardboard, PVC flooring | Quick and precise cutting of soft material and flexible, abrasive materials; |

| ATZ 52 SC | Carpets, mortar, concrete, tile adhesive | Scraping on a hard substrate; |