Working advice

- Pull the plug out of the socket before carrying out any work on the power tool.

To drill, loosen the locking brake (29) until the star handle (17) is easy to move. When doing so, hold the star handle in place to prevent the power tool from sliding down in an uncontrolled manner.

Start drilling in first gear at a low speed until the core bit rotates in the material without vibrating. Then switch to second gear if necessary.

You should always adjust the contact pressure to the material you are drilling. Drill applying uniform pressure. If necessary, pull the core bit gently out of the drill hole to remove the wet/dry drilling debris from the diamond segments.

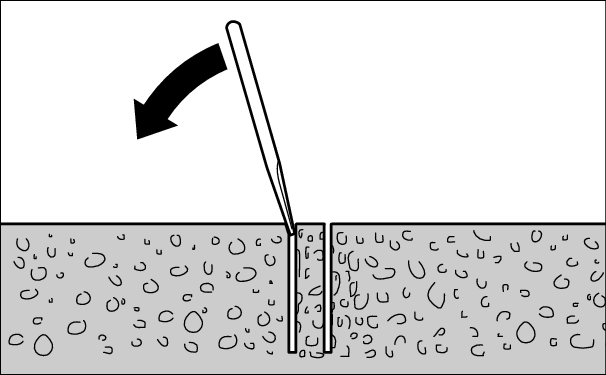

Use the star handle (17) to turn the power tool down to the required drilling depth. Then turn it back until the core bit is completely visible.

To reach the maximum possible working length, you will need to remove the drill core once it completely fills the core bit. Then insert the core bit back into the drilled hole and drill to the maximum depth.

If a core bit jams or snags, the power transmission to the drill spindle will be interrupted. If this happens, switch the power tool off immediately to prevent wear and heat build-up.

Dislodge the core bit by turning it to the right and left using a suitable open-ended spanner. Carefully pull the power tool out of the bore hole as you do so.

If the overload threshold is exceeded, the power tool will start noticeably pulsating. Reduce the contact pressure until the power tool starts working normally again.

If the contact pressure is not reduced, the power tool will switch off. You will be able to switch the power tool on again straight away, but you should now continue working with a lower contact pressure.

Wet drilling: Once drilling is complete, allow the water to keep flowing for a short while to rinse out the debris between the core bit and the drill core itself.

If the drill core is tightly seated in the core bit, hit the core bit with a piece of soft wood or plastic to loosen the drill core. If necessary, push the drill core out through the shank of the core bit using a rod.

Note: Do not hit the core bit with hard objects, as this may damage or deform it.