Safety Instructions for Pressing Machines

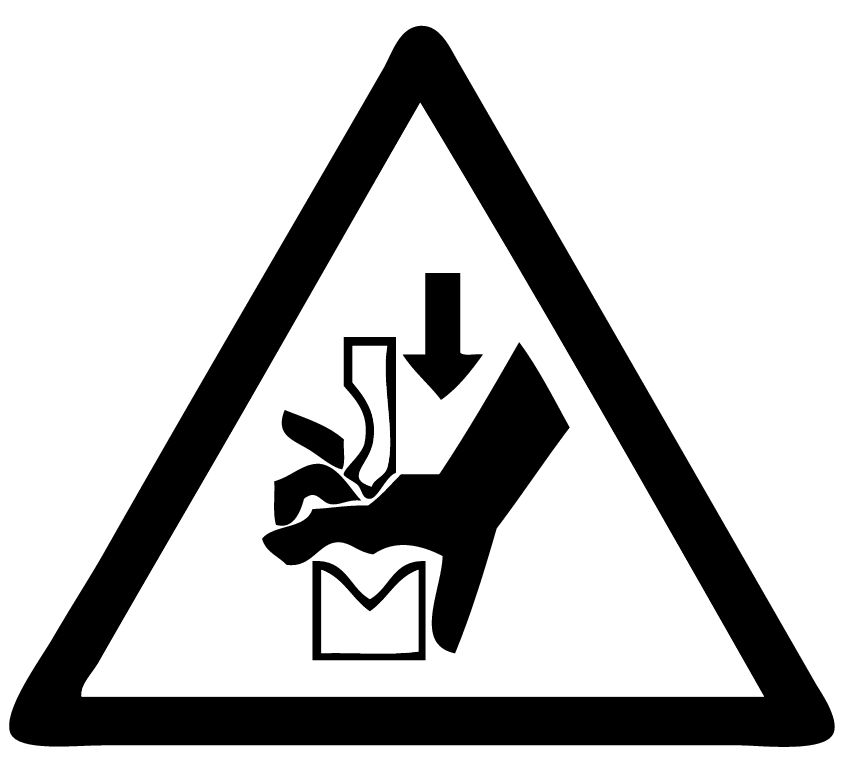

Always keep fingers and other parts of the body away from the work area of the cylinder and the press jaws, incl. the adapter jaws or press rings. Fingers and other parts of the body may be squashed and subsequently injured.

- Wear protective glasses while working with the power tool. In the event of a disturbance, this will protect your eyes against escaping hydraulic fluid and parts flying around.

- The power tool must only be operated by trained professionals who are aged 16 or over. This will reduce the danger to persons.

- The power tool must only be operated by one person. Direct other persons out of the hazardous zone of the power tool. This will reduce the danger to persons.

- Only operate the power tool if the tool head is visible and you can ensure that no limbs are in the danger zone. This will allow you to avoid injury.

- Only operate the power tool by hand. The on/off button and the reset button must be within reach so that they can be pressed in an emergency.

- The pressing machine must only be used with a press jaw inserted. The press jaw must be in perfect technical condition. Never attempt to repair damaged press attachments (press jaw, press ring, ring jaw, etc.). Dispose of the damaged press attachment in its entirety. A press attachment that has been welded, ground, drilled or modified in any other way may break during the pressing process and cause severe injury. If the press attachment is not replaced in its entirety, this may lead to component failures and severe injury.

- Only use appropriate press jaws and press fitting systems recommended by Bosch. Using unsuitable combinations of press jaws and press fittings may result in incomplete joining.

- After inserting the press jaw, check whether the lock is firmly locked in place. This will ensure that the press jaw does not inadvertently come loose during operation.

- If the power tool is so severely damaged that electrical parts or drive components are exposed, stop work immediately. Remove the battery and have the power tool repaired by the Bosch after-sales service. Improper repairs could result in significant danger to the user.

- Once the installation work is complete, use suitable test equipment to check the pipe system for leaks.

- Never carry out pressing operations within gas pipeline networks, unless the system provider has expressly authorised the use of this tool with specially tested press fittings for this purpose.

- Comply with the installation guidelines provided by the manufacturers of the press fitting and pipes.

- Use the power tool for a maximum of 4 pressing operations per minute. This will prevent the power tool from overheating.

- Do not press any live electrical parts. There is a risk of electric shock.

- If you are working in an elevated position, secure the power tool sufficiently using a fall protection system and ensure that there are no persons below the work area. Wear protective headgear when carrying out overhead work. This will enable you to avoid material damage and personal injury if you inadvertently drop the power tool.

- Improper repairs could result in significant danger to the user. Only use the pressing machine if it is in perfect technical condition. Have any damage repaired by the Bosch after-sales service immediately. Improper repairs could result in significant danger to the user.

- Maintenance and repair work must only be performed by specialist workshops authorised by Bosch. Improper repairs could result in significant danger to the user.

- In the event of a disturbance during the pressing process, press the reset button and let go of the ON switch. Hold the reset button down until the motor switches off. The valve will open and the cylinder will return to the starting position. You can therefore avoid personal injury and material damage.

- In the event of oil loss, the power tool must be sent back to the manufacturer.

- Avoid contact with leaking hydraulic fluid. Clean your skin thoroughly with soap and water in the event of any contact. Rinse your eyes immediately with plenty of water for at least 10 minutes in the event of any contact. Contact with hydraulic fluid can cause irritation and allergic reactions.

- Do not operate the power tool in an explosive environment.

- Only remove the battery once the power tool has been shut down safely.

- Do not open the power tool. Safe operation is then no longer guaranteed and the warranty claim becomes void.

- In case of damage and improper use of the battery, vapours may be emitted. The battery can set alight or explode. Ensure the area is well ventilated and seek medical attention should you experience any adverse effects. The vapours may irritate the respiratory system.

- Do not modify or open the battery. There is a risk of short-circuiting.

- The battery can be damaged by pointed objects such as nails or screwdrivers or by force applied externally. An internal short circuit may occur, causing the battery to burn, smoke, explode or overheat.

- Only use the battery in the manufacturer's products. This is the only way in which you can protect the battery against dangerous overload.

| Protect the battery against heat, e.g. against continuous intense sunlight, fire, dirt, water and moisture. There is a risk of explosion and short-circuiting. |