CYL-9 SoftCeramic Tile Drill Bit

For rotary drills/drivers, For impact drill/drivers

CYL-9 SoftCeramic Tile Drill Bit is the standard choice when drilling in tiles

- Dry drilling without lubrication for convenient use

- Simple flute-less design is especially suitable for drilling through tiles

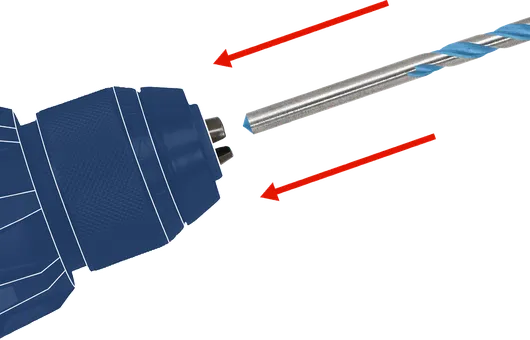

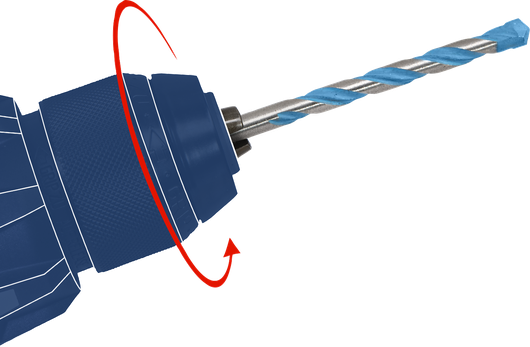

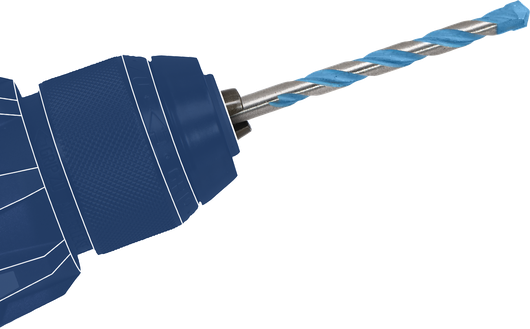

- Cylindrical shank compatible with three-jaw drill chucks

Materials

Select options

Diameter (D) mm 9 options

Total length mm 3 options

Choose a pack size 1 Pcs

Fits tools of most brands

Cylindrical shank compatible with three-jaw drill chucks

Standard for Drilling in Tiles

CYL-9 SoftCeramic Tile Drill Bit is the standard choice when drilling in tiles

- Simple flute-less design is especially suitable for drilling through tiles

- For drilling without impact at low speeds

Product Options

Available product options: 9

|

Part number

|

Diameter (D) mm

|

Total length mm

|

Pack quantity

|

|

|---|---|---|---|---|---|

| 2 608 587 158 | 4.00 | 70 | 1 Pcs | Find a local dealer | |

| 2 608 587 159 | 5.00 | 70 | 1 Pcs | Find a local dealer | |

| 2 608 587 161 | 6.00 | 80 | 1 Pcs | Find a local dealer | |

| 2 608 587 163 | 7.00 | 80 | 1 Pcs | Find a local dealer | |

| 2 608 587 164 | 8.00 | 80 | 1 Pcs | Find a local dealer | |

| 2 608 587 165 | 10.00 | 90 | 1 Pcs | Find a local dealer | |

| 2 608 587 166 | 12.00 | 90 | 1 Pcs | Find a local dealer | |

| 2 608 587 167 | 14.00 | 90 | 1 Pcs | Find a local dealer | |

| 2 608 587 168 | 16.00 | 90 | 1 Pcs | Find a local dealer |

out of products

Frequently asked questions

The HEX shank has several benefits over the CYL shank. While both shank types fit into three-jaw chucks of a standard drill, the HEX shank offers a more secure connection: due to its geometry it won’t slip in the chuck. The HEX shank ensures maximum power transfer from your machine to the drill bit. The HEX shank also gives you more flexibility when choosing your tool: you can use it with standard drills with three-jaw chucks as well as impact drivers with ¼” internal hexagon tool holders. The 3-wing shank of our CYL-5 drill bits only fits three-jaw chucks, but otherwise it offers benefits similar to those of the HEX shank: it fits in the chuck securely, it doesn’t slip and ensures maximum power transfer from your machine to the drill bit.

CYL-9 SoftCeramic: Suitable for soft ceramic tiles and non-tempered glass. HEX-9 HardCeramic: Suitable for soft and hard ceramic tiles, stone tiles, roof tiles and non-tempered glass. This drill bit is designed for drilling into tiles up to 10 mm thick. It’s not suitable for drilling into blocks. If you don’t know the hardness of the ceramic tile you need to drill into, we recommend using HEX-9 HardCeramic drill bits, as they can tackle both soft and hard ceramic tiles.

The number of holes you can drill depends on several parameters, such as the drill bit’s diameter, the pressure applied during drilling, the drilling direction and the material’s thickness and hardness. When testing 6 mm-diameter drill bits we got the following results: drilling with CYL-9 SoftCeramic bits you can expect to get 50+ holes in soft tiles, while HEX-9 HardCeramic bits should allow you to make 100+ holes in soft tiles and 10+ holes in hard tiles. We carried out the tests drilling manually in horizontal direction, using GSB 18V-85 in 1st gear and rotary mode with force of 200 N applied into 8 mm thick ceramic tile with PEI 5.

A tile’s hardness is not always easy to determine. The Mohs scale or PEI rating is often used to indicate the grade of the material’s hardness. The price of the tile can also help you estimate its hardness: hard tiles normally cost more than the soft ones. The size of your tile can be an indicator as well. The tiles 30x30 cm or larger are normally hard (as, otherwise, considering their size, they would easily break).

You should set your power tool to gear 1 not to overheat the drill bit. If you’re using a corded tool, in addition to setting it to gear 1, you also need to control the speed by pushing the trigger halfway only in order not to go over 500 rpm (as, otherwise, it will go up to 1000 rpm). If you’re using a cordless tool, you don’t need to control the speed through the trigger once the tool is set to gear 1, due to cordless tools’ lower rpm limit. If your tool doesn’t have gears, keep the speed at low rpm (max. 500 rpm), using the trigger.

Always set your power tool to the rotary mode only. Never apply the impact mode, as using this mode will damage the drill bit and the tile.

Always set your power tool to the rotary mode only. Never apply the impact mode, as using this mode will damage the drill bit and the tile. You should set your power tool to gear 1 to prevent the drill bit from overheating. If you’re using a corded tool, in addition to setting it to gear 1, you also need to control the speed by pushing the trigger halfway only in order not to go over 500 rpm (as, otherwise, it will go up to 1000 rpm). If you’re using a cordless tool, you don’t need to control the speed through the trigger once the tool is set to gear 1, due to cordless tools’ lower rpm limit. If your tool doesn’t have gears, keep the speed at low rpm (max. 500 rpm), using the trigger. Make sure you apply sufficient, but not excessive pressure (15-20 kg is recommended). You should hear a scraping or screeching noise when the drill bit starts removing the material. This normally confirms you’ve applied the right amount of pressure, the drill bit is working correctly and you can carry on drilling. Cooling is not required. Adding a little bit of ‘wobbling’ motion when drilling in hard tiles can help you gain speed and extend the drill bit’s lifetime. Once you’ve drilled through the tile, switch to a concrete drill bit to tackle the material under the tile (concrete, brick). Make sure you’ve changed the power tool settings to the impact mode and gear 2 before starting to drill with a concrete drill bit. For this specific application, consider our set including HEX-9 HardCeramic and CYL-3 (2608900596) drill bits. When drilling into hard tiles with diameters of 10 mm or larger, we recommend pre-drilling with smaller diameters (6, 7 or 8 mm).

Cooling can help extend the lifetime of your drill bit if applied in the right way, but you don’t need to apply it. When drilling in hard stone, we recommend letting the drill bit cool down each time you drilled a hole.