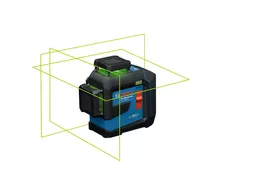

Laser levels are versatile tools suited to a wide range of jobs around the jobsite. For example, they can be used indoors to mark placements for windows or to ensure shelves are level when mounting. Self-levelling line lasers are also great to use for pipe and wall tile installations, as they can display the correct angles quickly.

This makes them vital tools for many tradespeople, including carpenters, electricians, builders, plumbers, and HVAC technicians. Self-levelling capabilities and multiple laser lines help labourers perform quick markups and squaring tasks, and most models are designed for improved efficiency when working across standard levelling and transfer applications.

Line lasers provide a very high degree of accuracy, typically around 0.02 or 0.03 mm/m, which helps workers on both small and large-scale projects measure precisely. In certain models, you can also measure the self-levelling range of the device, which is usually around 4°. Laser diodes are generally 630-650 nm.

All these features enhance your work quality. This leaves your customers and clients more satisfied and boosts your reputation as a reliable tradesperson. That’s why laser levels should be an essential piece of kit in your toolbox.